Menu

- About Us

- Products & Services

- FABRICATION

- Heat Exchanger & Pressure Vessel

- Boiler

- Cogen / Open Cycle / Combined Cycle

- Data Center

- Renewable

- Portfolio

- Investors

- News

- Career

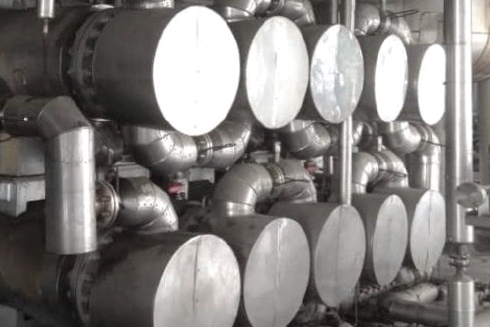

KAWAN heat exchangers are designed and built to ASME code and TEMA standards. As a member of the Heat Transfer Research Institute (HTRI), we keep abreast of advancements in heat transfer while continuously improving in production technology, allowing us to supply custom-made heat exchangers with the best efficiency, assuring quality at affordable prices. All Heat Exchangers can come with Malaysia DOSH certification.

We specialise in high-quality pressure vessel fabrication conforming to international codes such as ASME U & U2, PED, and are also approved by DOSH Malaysia.

The range of authentic materials we are experienced in includes carbon steel, stainless steel (304, 316L, 317L, 904L), duplex and super duplex (2205, 2507), Hastelloy, and titanium, along with internal linings such as glass-lined, PTFE, FRP, and rubber.

Operating across four factories with a combined 45,000 m² land area and approximately 20,000 m² of covered workspace, we produce an average of over 500 tanks annually. Our facilities feature Automated Polishing, Dish End Forming, Orbital & Plasma Welding, Automatic TIG Welding, and more. Our products are trusted worldwide, spanning Indonesia, the Philippines, Thailand, Vietnam, Saudi Arabia, Africa, Italy, Germany, South Africa, and the USA